Minimizing Gear and Bearing Wear with Stretch Wrap Machine Repair Near Me

Wiki Article

Comprehending the Relevance of Specialist Stretch Wrap Machine Repair Service for Optimal Performance

Stretch Wrap makers play a crucial role in the effectiveness of production and logistics operations. However, they can experience malfunctions that interrupt operations. Recognizing these concerns early is important for lessening downtime. Expert repair work services provide a remedy, yet many companies neglect their significance. Understanding the benefits of timely repair work can greatly impact operational performance and expense monitoring. What aspects should services take into consideration when seeking specialist fixing solutions for their stretch Wrap equipments?The Role of Stretch Wrap Machines in Manufacturing and Logistics

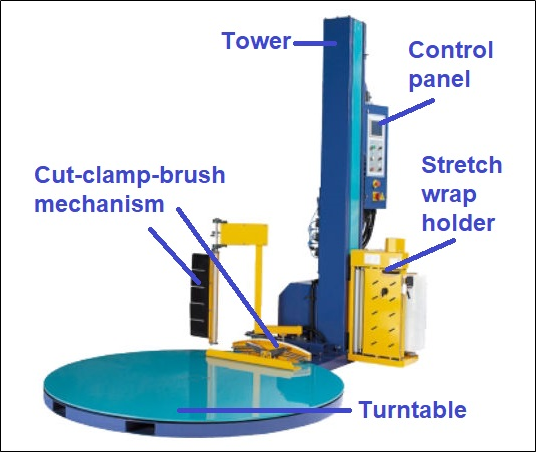

Stretch Wrap equipments play a necessary duty in the performance of production and logistics procedures. These equipments automate the process of securing products on pallets, boosting stability throughout transportation and storage. By firmly covering goods in plastic film, stretch Wrap machines lessen the risk of damages triggered by shifting or outside effects. This not only secures the honesty of the items but additionally decreases waste and the requirement for additional product packaging materials.In production settings, stretch Wrap devices add to structured workflows, permitting faster packing and delivery processes. They make it possible for business to manage higher volumes of items, enhancing total efficiency. In logistics, the usage of stretch Wrap equipments guarantees that products are appropriately protected for transport, decreasing the chance of item loss or damages in transportation. By enhancing load stability, these makers inevitably support economical operations, making them important possessions in modern-day supply chains.Typical Indicators of Stretch Wrap Machine Malfunction

When a stretch Wrap Machine begins to breakdown, certain indications can show the requirement for immediate interest. One typical indicator is inconsistent wrapping tension, which may lead to loose or excessively limited wraps, compromising item stability. Additionally, uncommon sounds throughout procedure, such as clunking or grinding, can indicate mechanical problems that need assessment. A reduction in covering rate or failure to finish cycles can also indicate underlying problems, possibly leading to operational hold-ups. One more sign is the existence of film jams, where the wrapping product becomes stuck, interrupting the process. If the Machine shows error codes or advising lights on its control board, these notifies must not be overlooked. Noticeable wear on elements, such as rollers or movie dispensers, might recommend that upkeep or repair work is required to restore peak capability. Acknowledging these signs early can prevent further complications and assurance efficient operation.The Impact of Downtime on Procedures

Downtime of stretch Wrap equipments can substantially influence a company's monetary efficiency, causing significant monetary losses. Furthermore, manufacturing hold-ups may disrupt supply chains and consumer complete satisfaction, more exacerbating the influence on operations. Understanding these repercussions is essential for efficient Machine upkeep and repair service approaches.

Financial Loss Assessment

The impact of tools failure can considerably interfere with procedures, bring about significant financial losses. When a stretch Wrap Machine breakdowns, manufacturing might stop, resulting in disgruntled customers and unfinished orders. This downtime not only influences prompt revenue however can likewise harm long-lasting organization connections. The prices associated with repair work, combined with shed productivity, can quickly build up, straining budget plans. In addition, companies may sustain additional expenditures from overtime incomes for staff that require to compensate for shed time once the Machine is functional once more. In an open market, such economic influences can prevent a business's growth and earnings. Therefore, professional and timely repair solutions are necessary to lessen downtime and safeguard economic health and wellness.Manufacturing Delays Consequences

Equipment failure can cause significant manufacturing delays, affecting different elements of procedures. When a stretch Wrap Machine breakdowns, the immediate effect is stopped product packaging procedures, which can produce a stockpile in manufacturing schedules. This disruption not only influences the circulation of products however also pressures labor sources, as staff members might be compelled to stand still or redirect efforts to various other jobs. Consequently, hold-ups can result in unmet distribution deadlines, tarnishing consumer partnerships and possibly leading to lost sales. In addition, downtime sustains added costs connected to fix solutions and overtime wages for workers. Inevitably, the causal sequence of manufacturing hold-ups shows the crucial requirement for timely and expert maintenance of stretch Wrap machinery to assure smooth functional continuity.

Benefits of Expert Repair Service Solutions

Professional fixing services for stretch Wrap machines provide numerous essential advantages. These solutions not just enhance equipment long life but likewise add to boosted functional efficiency and provide affordable maintenance remedies. By spending in professional repair work, businesses can guarantee their equipments execute at peak performance in time.Enhanced Equipment Longevity

Purchasing specialist fixing solutions for stretch Wrap equipments substantially improves their long life. Routine upkeep and prompt repairs attend to possible concerns before they rise, ensuring that makers run at their ideal. Competent professionals make use of specialized understanding and devices to determine and remedy troubles that might not appear to untrained operators. This aggressive technique decreases damage, thereby prolonging the lifespan of the tools. Furthermore, the use of high quality replacement parts throughout repairs even more contributes to toughness. Therefore, business can avoid the costs related to premature tools failing and substitute. On the whole, specialist fixing services play an important function in maintaining the stability and capability of stretch Wrap makers, inevitably protecting their long-lasting investment.Raised Operational Efficiency

Preserving stretch Wrap equipments via professional fixing solutions substantially improves functional efficiency. Professional repair service guarantees that all parts function at their finest, lowering the possibility of breakdowns that disrupt production routines. When equipments remain in peak condition, they can run at their created rate and precision, causing faster wrapping processes. This efficiency reduces downtime and enables for smoother process, inevitably enhancing productivity. In addition, well-maintained equipments require less energy to run, adding to improved source management. By addressing mechanical concerns quickly, expert repair service solutions stop small troubles from escalating right into significant failings, ensuring that procedures run seamlessly. Subsequently, business can attain greater output levels, fulfill client demands more successfully, and maintain a competitive edge in the market.Economical Upkeep Solutions

A well-executed repair service can greatly decrease long-lasting maintenance expenses for stretch Wrap equipments. click for info By resolving concerns promptly and efficiently, professional repair work services decrease the threat of substantial damage that can require costly replacements. Normal upkeep and prompt repair services guarantee that equipments operate at peak performance, lowering power consumption and material waste. his explanation Additionally, proficient professionals have the expertise to recognize underlying problems that may not be instantly noticeable, avoiding future breakdowns. Spending in expert fixing services likewise extends the life-span of the tools, supplying substantial savings with time. Overall, these affordable maintenance services not just boost the performance of stretch Wrap equipments but additionally add to a much more lasting operational budget plan.Preventative Maintenance for Stretch Wrap Machines

Dependability in stretch Wrap makers depends upon effective preventative maintenance techniques. Routine upkeep is important to assure peak performance and long life of the devices. This entails routine assessments, lubrication of moving components, and prompt replacement of used parts - stretch wrap machine repair near me. By sticking to an organized upkeep schedule, drivers can identify possible concerns before they intensify right into considerable issues, thereby reducing downtime and costly repairs.Additionally, cleaning the Machine from debris and residue is crucial, as it can impact functionality and speed. Operators ought to additionally check the stress on the covering movie and readjust setups as required to avoid movie damage and warranty secure tons. Training staff on correct procedure and upkeep methods better enhances dependability. Inevitably, carrying out a detailed preventative upkeep plan not just expands the life of stretch Wrap equipments yet also contributes to the total performance of product packaging proceduresSelecting the Right Repair Service Service for Your Equipment

Often Asked Inquiries

Just How Commonly Should Stretch Wrap Machines Be Examined for Upkeep?

Stretch Wrap machines must you can check here be examined for upkeep at the very least every 6 months (stretch wrap machine repair near me). Regular assessments assist recognize prospective concerns early, making sure the machines operate successfully and decreasing the risk of pricey downtime or extensive fixingsCan I Perform Repairs on My Stretch Wrap Machine Myself?

While some small changes may be possible, trying considerable repair services on a stretch Wrap Machine can bring about further issues. It is typically advisable to get in touch with a professional technician for secure and reliable repair services.What Is the Average Lifespan of a Stretch Wrap Machine?

The average life expectancy of a stretch Wrap Machine commonly varies from 5 to ten years, relying on use strength, upkeep methods, and the quality of the Machine, influencing its overall efficiency and sturdiness gradually.Are There Certain Brands Understood for Better Sturdiness in Stretch Wrap Machines?

Particular brands, such as Signode and 3M, are identified for their durability in stretch Wrap equipments. Consumers usually report longer life expectancies and fewer maintenance concerns contrasted to various other brands, making them popular selections in the industry.How Can I Inform if My Machine Requirements an Upgrade As Opposed To Repair Work?

Indicators for upgrading a stretch Wrap Machine include constant malfunctions, outdated modern technology, raising operational prices, and lack of ability to meet manufacturing demands. Evaluating efficiency metrics can help identify whether repair or upgrade is the extra practical option - stretch wrap machine repair near me. By snugly wrapping items in plastic film, stretch Wrap machines lessen the danger of damage triggered by shifting or outside impacts. Professional fixing services for stretch Wrap makers offer a number of essential benefits. Investing in expert fixing services for stretch Wrap equipments significantly boosts their longevity. Preserving stretch Wrap equipments via expert repair work services significantly boosts operational effectiveness. A well-executed fixing service can greatly minimize lasting upkeep costs for stretch Wrap makersReport this wiki page